- Products Details

Quick Details

-

Brand Name: YORK

Model Number: YDEBCDK3 - DA D S

Place of Origin: Jiangsu, China (Mainland)

Packaging & Delivery

- Packaging Details: 180days

- Delivery Detail: --

Specifications

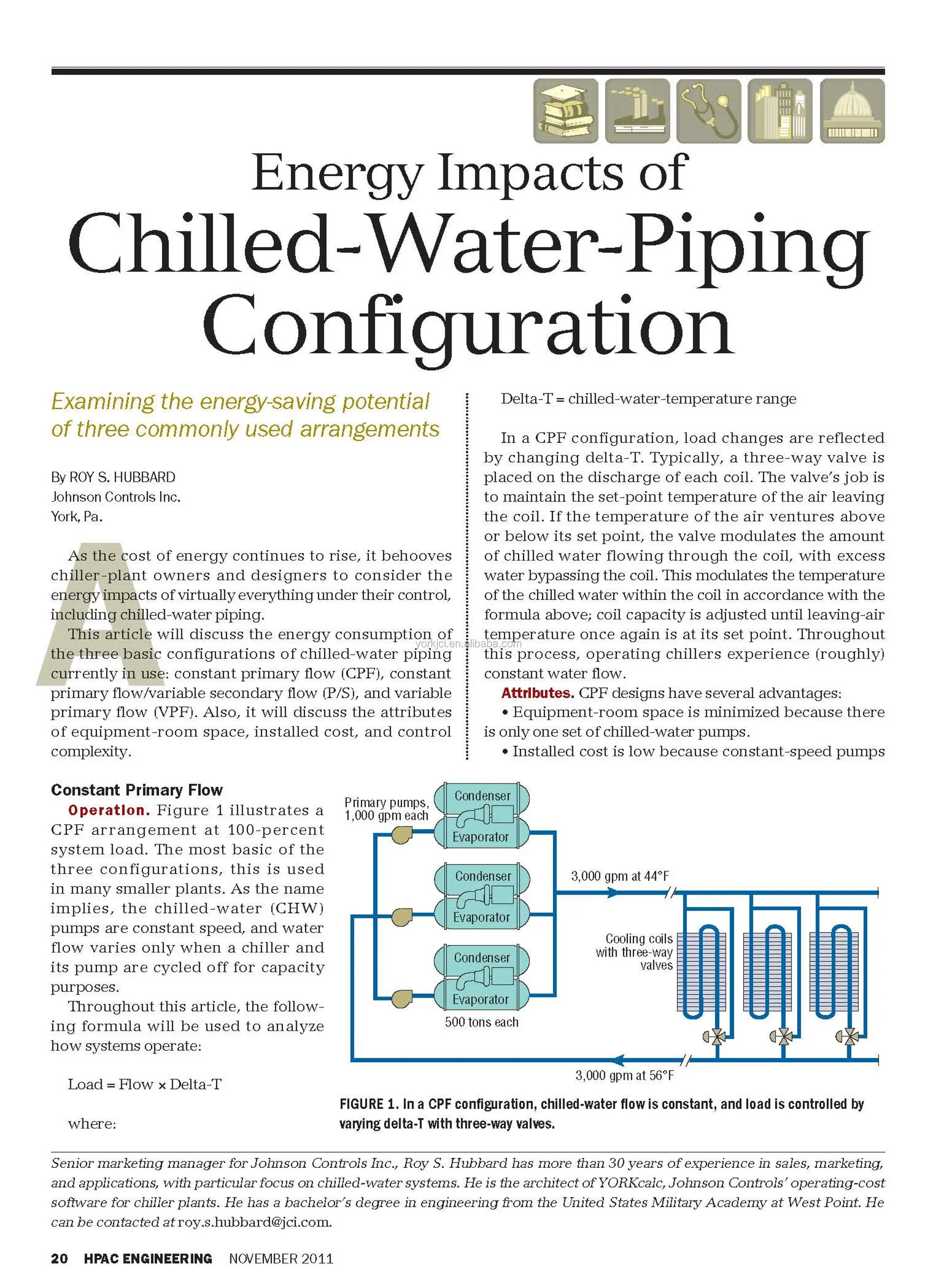

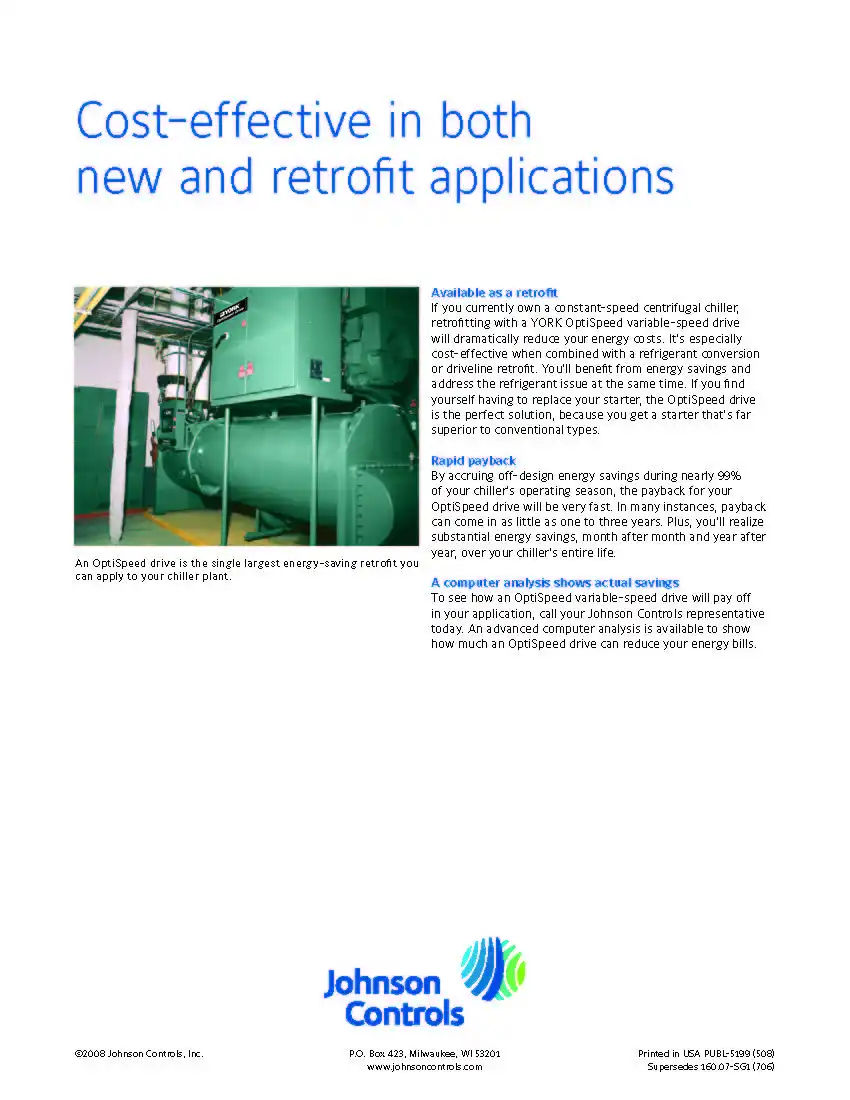

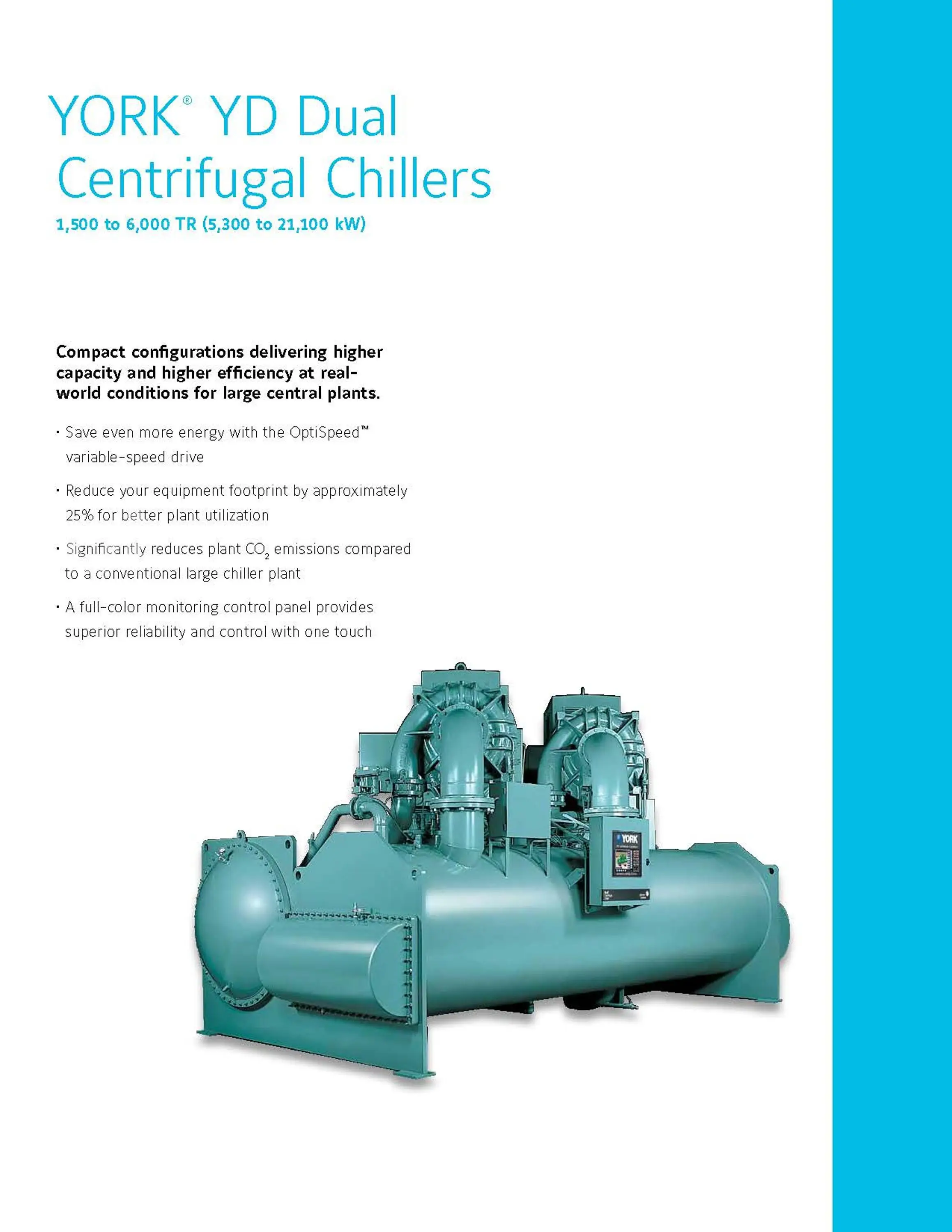

YD Dual Centrifugal Chiller

Get the superior performance you want from a chiller that takes up less space with our YD Dual Centrifugal Chiller from YORK®. At Johnson Controls, we've designed the YD Dual Centrifugal Chiller to feature compact configurations for real-world efficiency, energy savings through variable speed drive, environmental sustainability, and enhanced reliability though advanced controls.

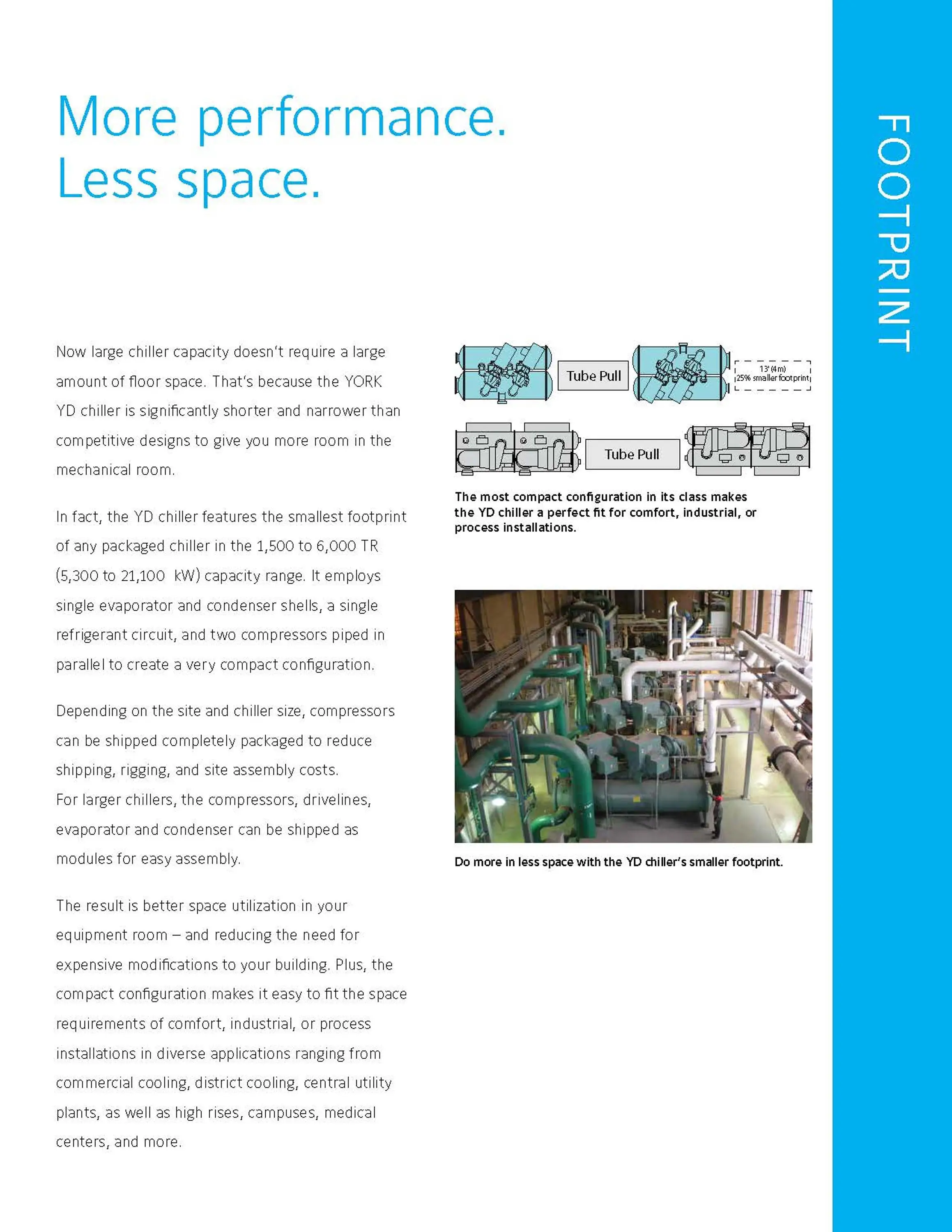

A perfect fit for comfort, industrial, or process installations, this chiller utilizes two York® centrifugal compressors operating in parallel and features the most compact configuration in its class.

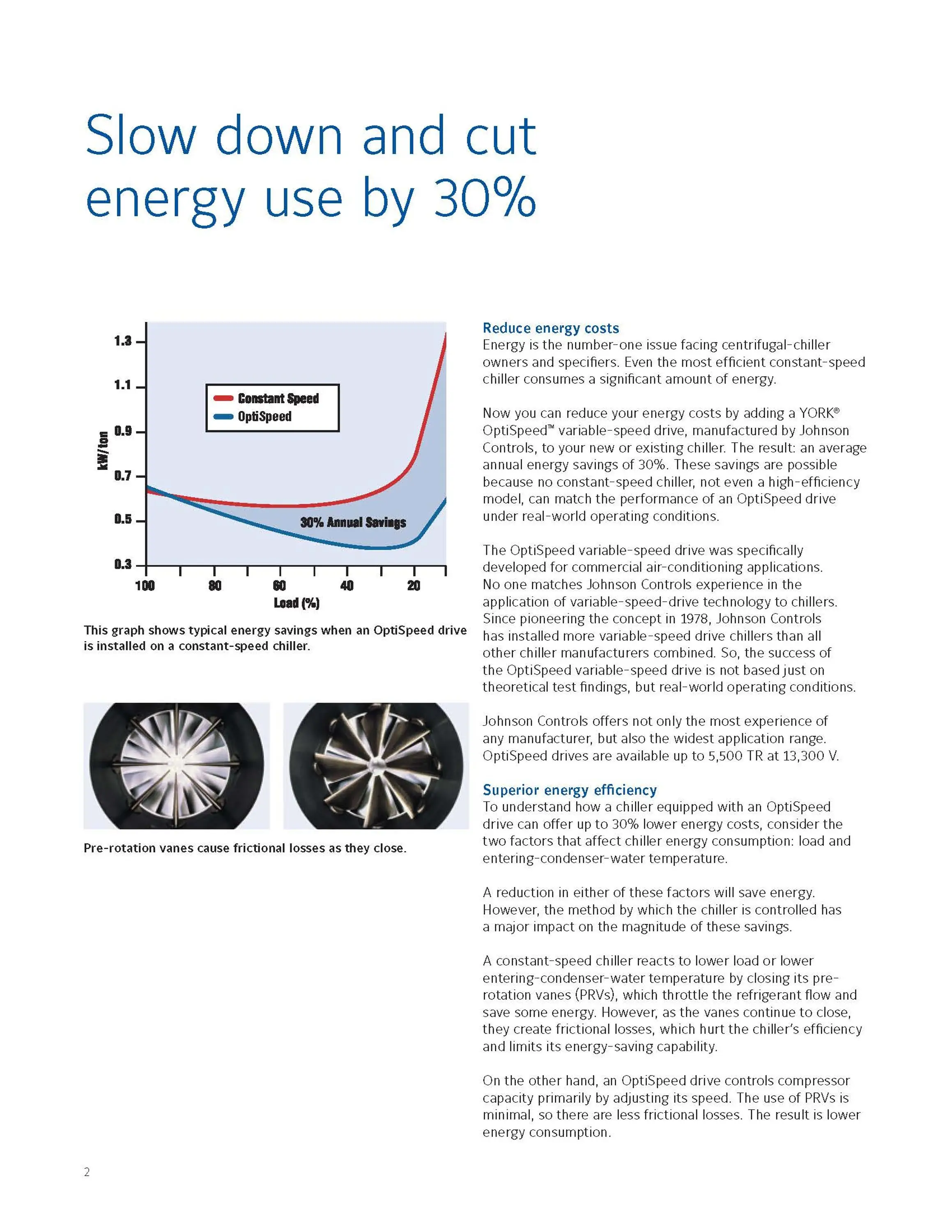

- Unsurpassed Energy Savings With the OptiSpeed™ Drive, energy consumption can be as low as .20 kW/TR, reducing annual energy costs by as much as 30%.

- Real-World Efficiency Designed for maximum efficiency in the real world, where 99% of the cooling season is spent at off design conditions. Save even more energy with the addition of the OptiSpeed-variable-speed drive.

- Environmental Responsibility HFC134a refrigerant has zero ozone depletion potential and low total global-warming potential.

- Earn LEED® Points Earn credits for Energy and Atmosphere (EAc1) and for Enhanced Refrigerant Management (EAc4).

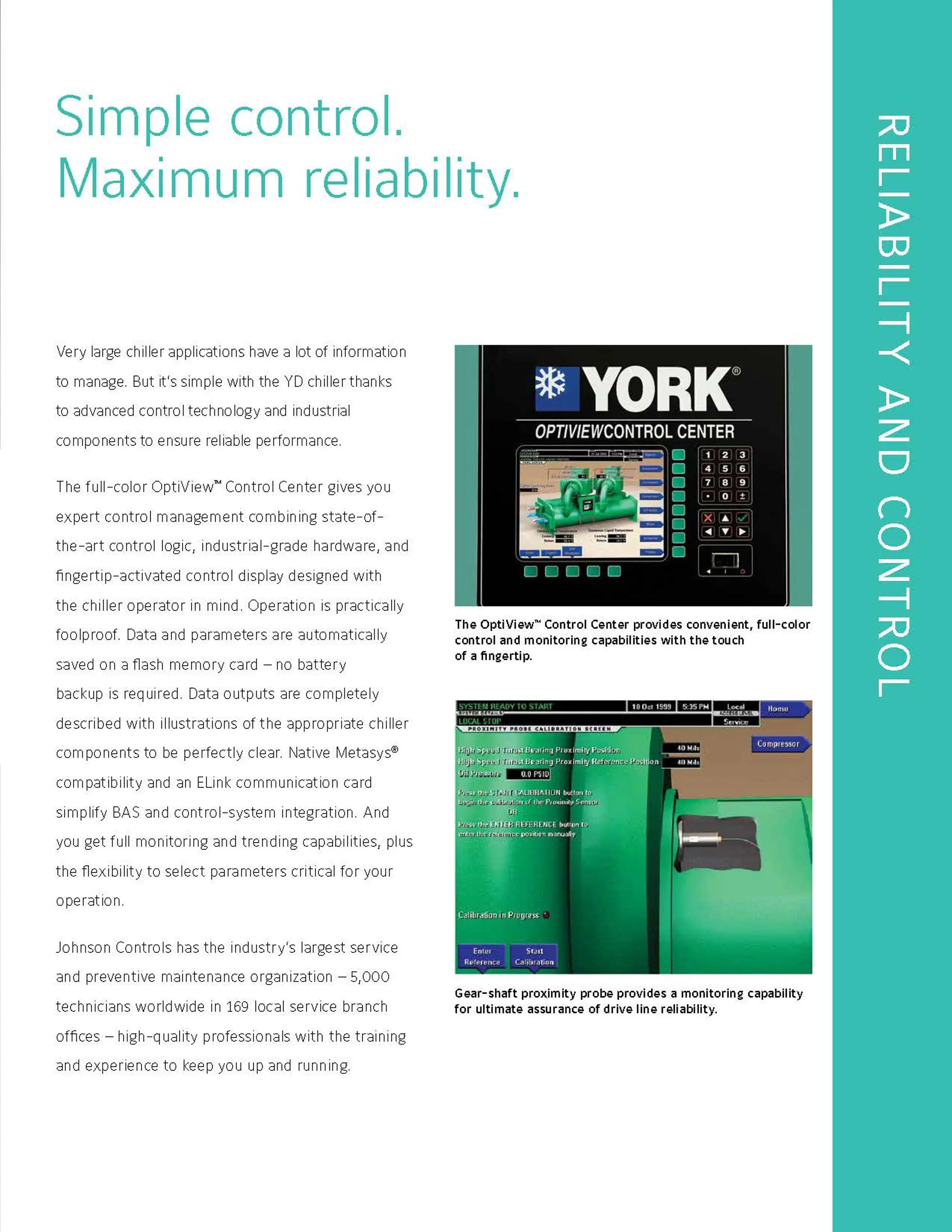

- Easy Operation The OptiView™ Control Center ensures optimum performance and easy operation.

- The YORK® YD™ chillers offer a complete combination of features for total owner satisfaction.

The YD line of chillers utilize two YORK centrifugal compressors operating in parallel

on a common set of heat exchanger shells to obtain large chiller capacities, and efficient

part load operation.

MATCHED COMPONENTS MAXIMIZE EFFICIENCY

Actual chiller efficiency cannot be determined by analyzing

the theoretical efficiency of any

one chiller component.

It requires a specific combination of heat exchanger, compressor,

and motor performance to achieve the lowest system kW/ton. YORK YD chiller technology

matches chiller system components to provide maximum chiller efficiency under actual –

not just theoretical operating conditions.

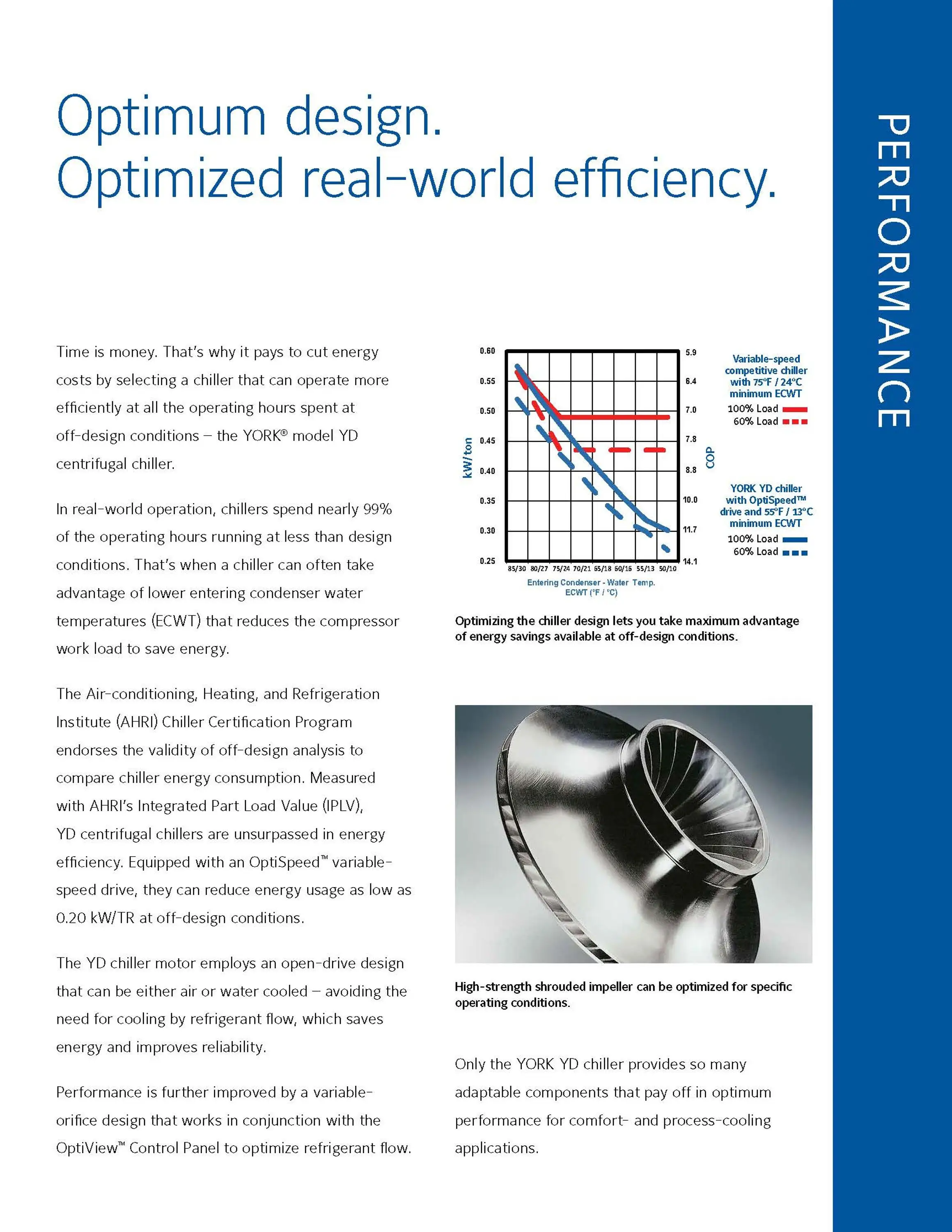

Real world energy performance

Johnson Controls pioneered the term “Real World Energy” to illustrate the energy saving

potential of focusing on chiller performance during off design conditions. Off design is not

only part load, but full load operation as well, with reduced entering condenser water temperatures

(ECWTs). Where chillers operate 99% of the time, operating costs add up.

YORK YD chillers are the only chillers designed to operate on a continuous basis with cold

ECWT and full condenser flow at all load points, taking full advantage of Real World conditions.

This type of operation benefits the cooling tower as well; reducing cycling of the fan

motor and ensuring good coverage of the cooling fill.

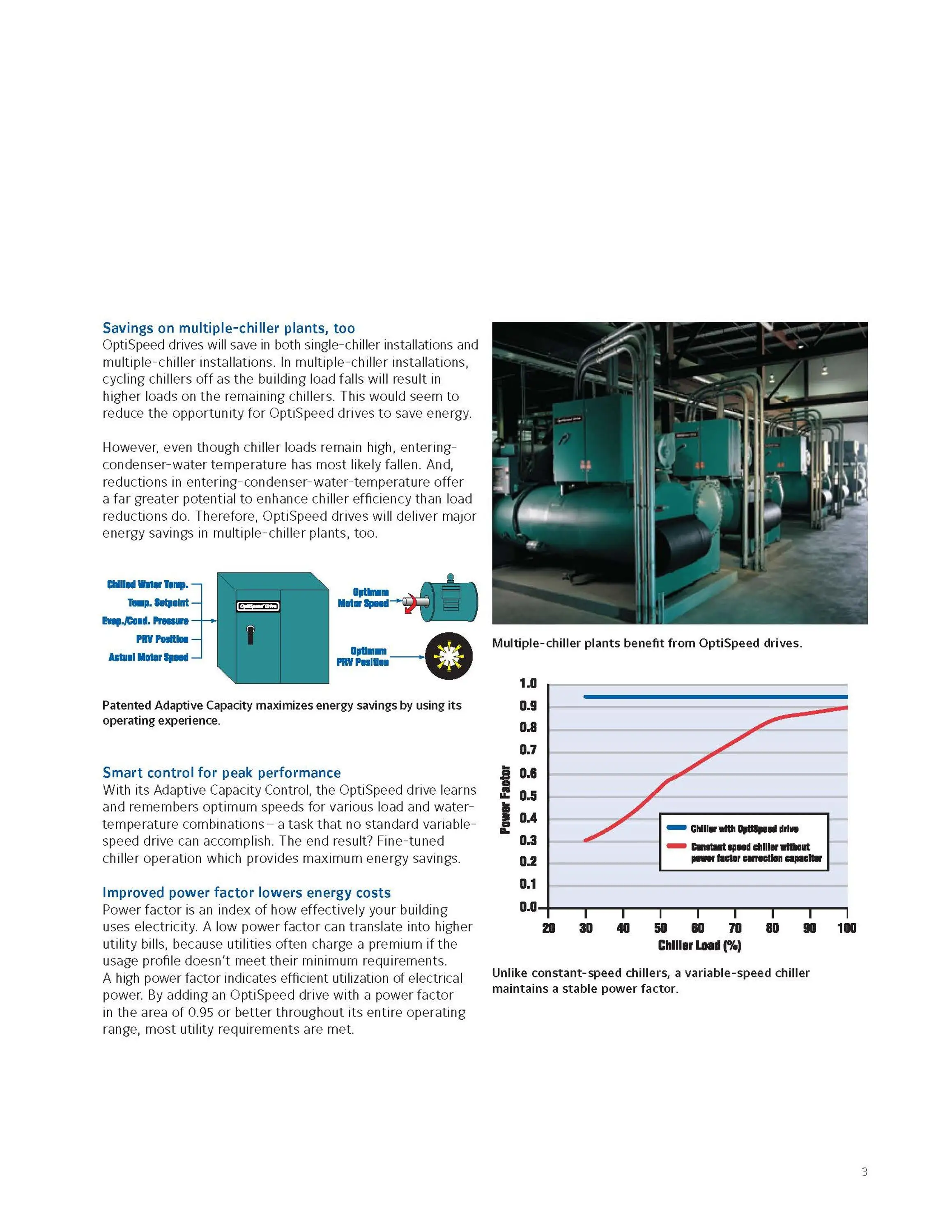

The YD dual compressor chiller provides further energy savings by running in single compressor

mode at part loads of 50% and lower. The chiller operates more efficiently by running

with a single more fully loaded compressor. The two compressors share a common

refrigerant circuit, thereby utilizing the full heat transfer surface available for part load single

compressor operation.

YORK YD chillers offer the most efficient Real World operation of any chiller, meaning lower

operating costs and an excellent return on your chiller investment.

OPEN DRIVE DESIGN

Hermetic motor burnout can cause catastrophic damage

to a chiller. The entire chiller must

be cleaned and the refrigerant replaced. YORK YD centrifugal chillers eliminate this risk by

utilizing air cooled motors. Refrigerant never comes in contact with the motor, preventing

contamination of the rest of the chiller.

Insurance companies that offer policies on large air conditioning equipment often consider

aircooled motors

a significant advantage over hermetic refrigerantcooled

units.

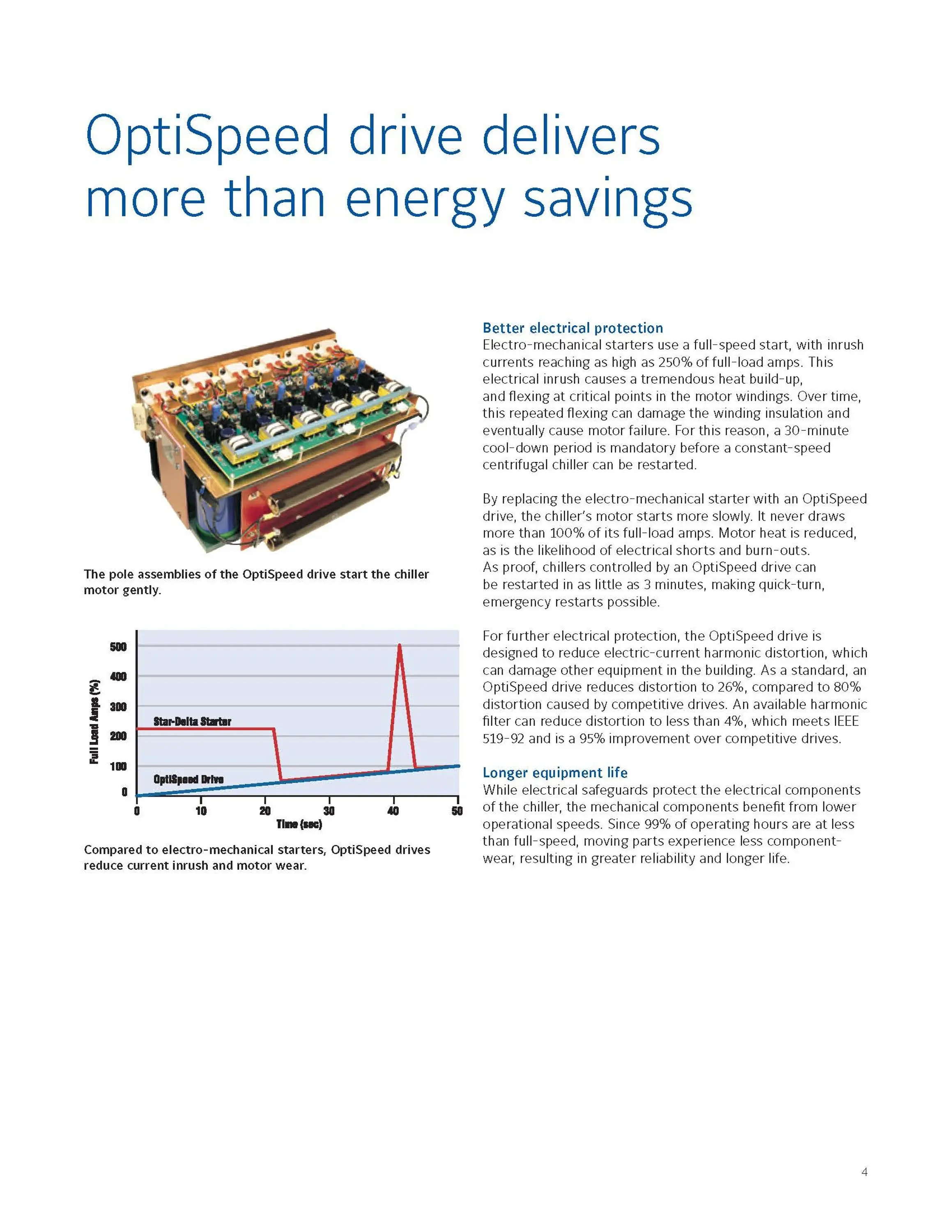

The YD chiller uses two motors, each roughly half the size of a motor used on an equivalent

size single compressor chiller. By staggering the start of these motors, the starting in-rush

current of each smaller motor is less (Electromechanical and Solid State Starter only). This

provides a lower burden on the building electrical system. Also, using two smaller motors

allows low voltage compressor drive motors to be applied on larger chillers. This can be an

advantage for applications where medium voltage power sources are not available HIGH EFFICIENCY HEAT EXCHANGERS

YD chiller heat exchangers offer the latest technology

in heat transfer surface design to

give you maximum

efficiency and compact design. Waterside and refrigerant side design

enhancements minimize both energy consumption and tube fouling.

SINGLE STAGE COMPRESSOR DESIGN AND EFFICIENCY PROVEN IN THE MOST

DEMANDING APPLICATIONS

Designed to be the most reliable chillers we’ve ever made, YORK YD centrifugal chillers

incorporate singlestage

compressor design. With fewer moving parts and straightforward,

efficient engineering, YORK singlestage

compressors have proven durability records in

the U.S. Navy, hospitals, chemical plants, gas processing plants, and in other applications

where minimal downtime is a crucial concern.

In thousands of installations worldwide, YORK single stage compressors are working to

reduce energy costs. High strength aluminum alloy compressor impellers

feature backward curved

vanes for high efficiency. Airfoil shaped pre rotation vanes minimize flow

disruption

for the most efficient part load performance. Precisely

positioned and tightly fitted,

they allow the compressor to unload smoothly from 100% to minimum load for excellent

operation in air conditioning applications.

Precision control of compressor oil pressure

Utilizing our expertise in variable speed drive technology and applications, Johnson Controls

has moved beyond the fixed head and bypass approach of oil pressure control. The

old approach only assures oil pressure at the outlet of the pump rather than at the compressor,

and allows no adjustment during chiller operation. The YD chillers feature two variable

speed drive oil pumps, monitoring and providing the right amount of oil flow to each compressor

on a continuous basis. This design also provides sophisticated electronic monitoring

and protection of the oil pump electrical supply, ensuring long life and reliable operation

of the oil pump motor. Variable speed drive technology reduces oil pump power consumption,

running only at the speed required, rather than at full head with a pressure regulating

bypass valve.

FACTOR Y PACKAGING REDUCES FIELD LABOR COSTS

YORK YD centrifugal chillers are designed to keep installation costs low. Where installation

access is not a problem, the H9, K1 and K2 compressor size YD dual compressor chillers

may be shipped completely packaged. In order to save on shipping and rigging costs,

larger K3 to K7 compressor size units are disassembled into four major components: two

drivelines, the evaporator, and the condenser. Piping break points are flanged, and wiring

connections are simple plug connections to ensure a simple chiller commissioning utilizing

a Variable Speed Drive or a factory-installed Solid State Starter.

York (Wuxi) air Conditioning and Refrigeration Co. Ltd, Located in Wuxi National High-tech Industrial Park, Jiangsu province, China. Covers an area of 60000 square meters, of which the heavy machine factory building takes up 14,000 square meters. At present, the company has about 500 staffs, in the field of large-size units. York Wuxi is the largest manufacturer in Asia –pacific region with an annual output of more than 3600 sets. Its products not only top on market share in China, but also see tremendous growth in export in recent years.

York Wuxi has six production lines in total, of which five are automated lines, including one air-cooled screw production line, one large-size water-cooled screw unit production line, one small-size water-cooled screw unit production line, and two centrifugal unit production line. All production line adapt the DFT technology, being the first in the industry. The entire work process is compact and rational. With the efficient management method (such as four-color light), these lines have become the most compact, most efficient and most advanced production line in the industry.

York Wuxi is equipped with globally advance equipment in every step of its production process, including:

Most advanced plasma digital cutter which can be used under water

Efficient digital plate bending machine with a roll length up to 4.8 meters

LINCO DC submerged arc welder imported from USA which is the most advanced equipment in the world.

Most advanced digital drill press in the industry.

Four large-sized chiller comprehensive performance test branches, (test capacity per set up to 2000 cold tons, for 10KV high voltage tests and frequency conversion tests), presenting the most advanced level in China.

YORK (CHINA) introduced the Performance Excellence Mode since the beginning of its operation. This mode adopted by most world-class enterprises focuses on the customers. It learns, meets and exceeds the customers’ needs and serves society through its human-oriented strategy and corporate culture. Based on the effective QEHS management system and advanced management tools (e.g. six-sigma).YORK (CHINA) consolidates its leading status in the industry.

1. YORK RESEARCH AND DEVELOPMENT

In December 2004, to provide high-quality and competitive air conditioning products and refrigeration equipments to the Asia-Pacific region and on the parts of the world, YORK set up the YORK Asia Pacific research and development center in

Wuxi.

The center has the most advanced software systems, highly qualified professionals, and various test equipments and systems. The air-cooled test bench, unique in China and the largest in the

Asia-Pacific region, which has complete spring base for the equipment vibration test, can lower the noise to 20db by means of muffle devices. It also can carry out the working environment temperature simulation test by changing the indoor temperature via air conditioning and refrigeration system.

Since its establishment, the R&D center is dedicated to development efficient, energy saving, environment friendly products with independent intellectual property and unique technology and to the research of thermal conductivity, noise vibration and reliability to meet the needs of refrigeration &air conditioning in China and even the entire Asia-Pacific region. At the same time, the R&D center is also working closely with YORK international’s R&D division to develop money advanced products that can meet the global needs, In fact, innovation and renovation of many core technologies are happening in the Wuxi center.

2. YORK SEVICES INTRODUCTION

York Air Conditioning & Refrigeration Service Centre was established in 1993 in Shanghai. The Service Centre is now having stations in Beijing, Nanjing, Guangzhou, Xiamen, Wuhan and Shenzhen, and service representatives in Shantou, Changsha, Chengdu, Jinan, Dalian, Harbin and Hangzhou, and so on. Using our established service center networks throughout China, we are able to provide full after-sales services to all our customers in China.

At the same time, the service center is having a bonded spare parts warehouse in Shanghai. The spare parts warehouse will serve the spare part needs for our customers with minimum delivery time.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Shanghai Jiusui-Ref Systems Engineering Co., Ltd is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.

Scale: Above 1000 People

Country/Region: China (Mainland)/Asia

Established: 2015