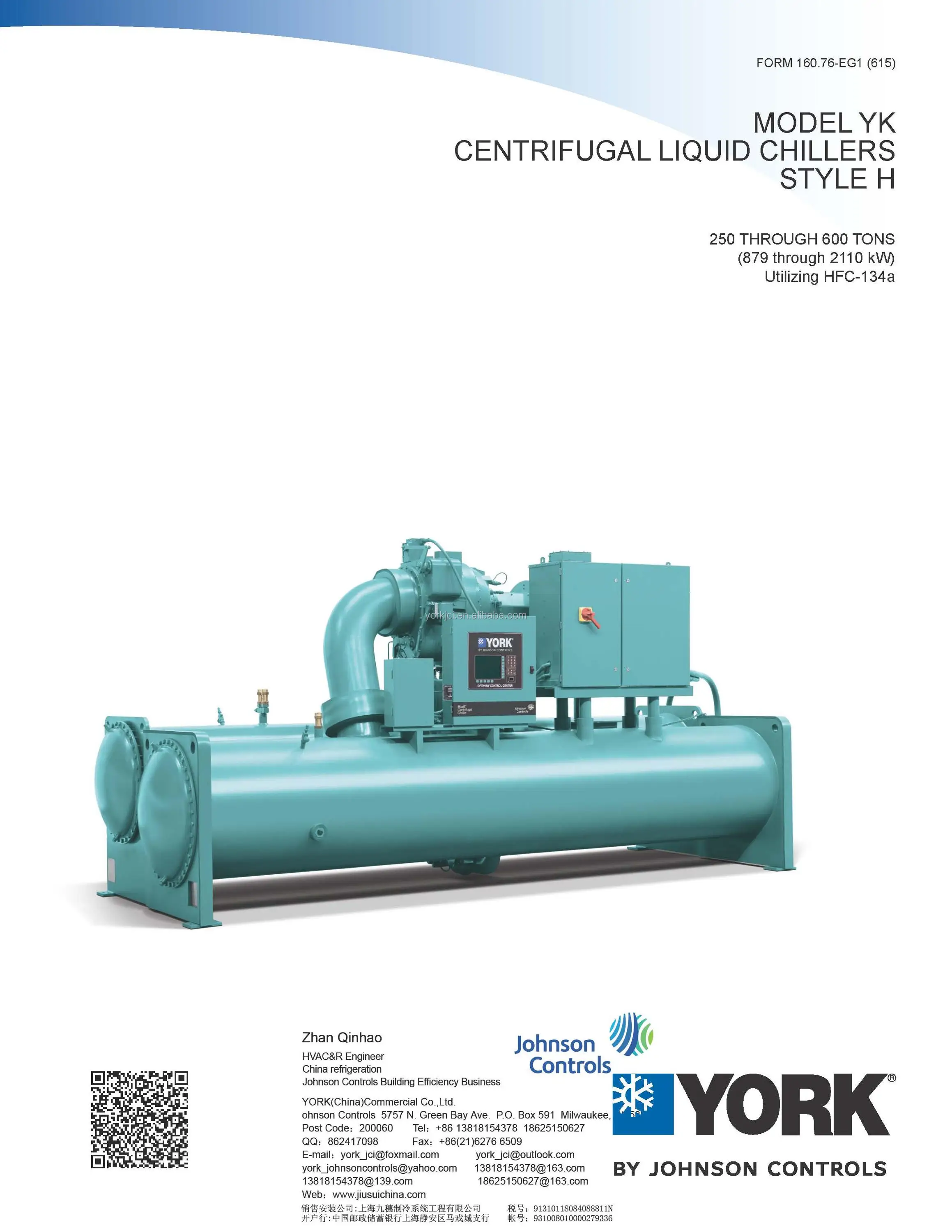

YK Centrifugal Chiller

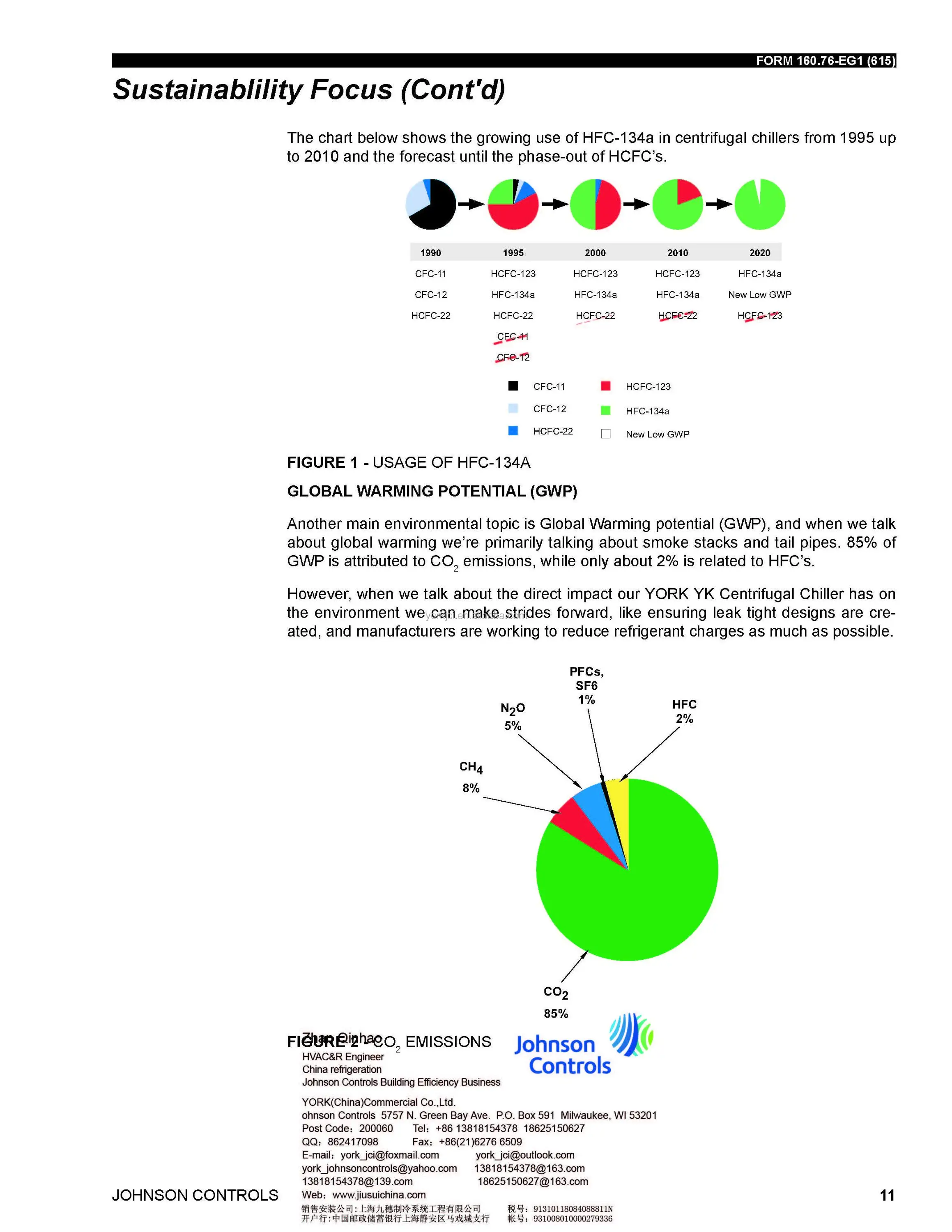

- Products Details

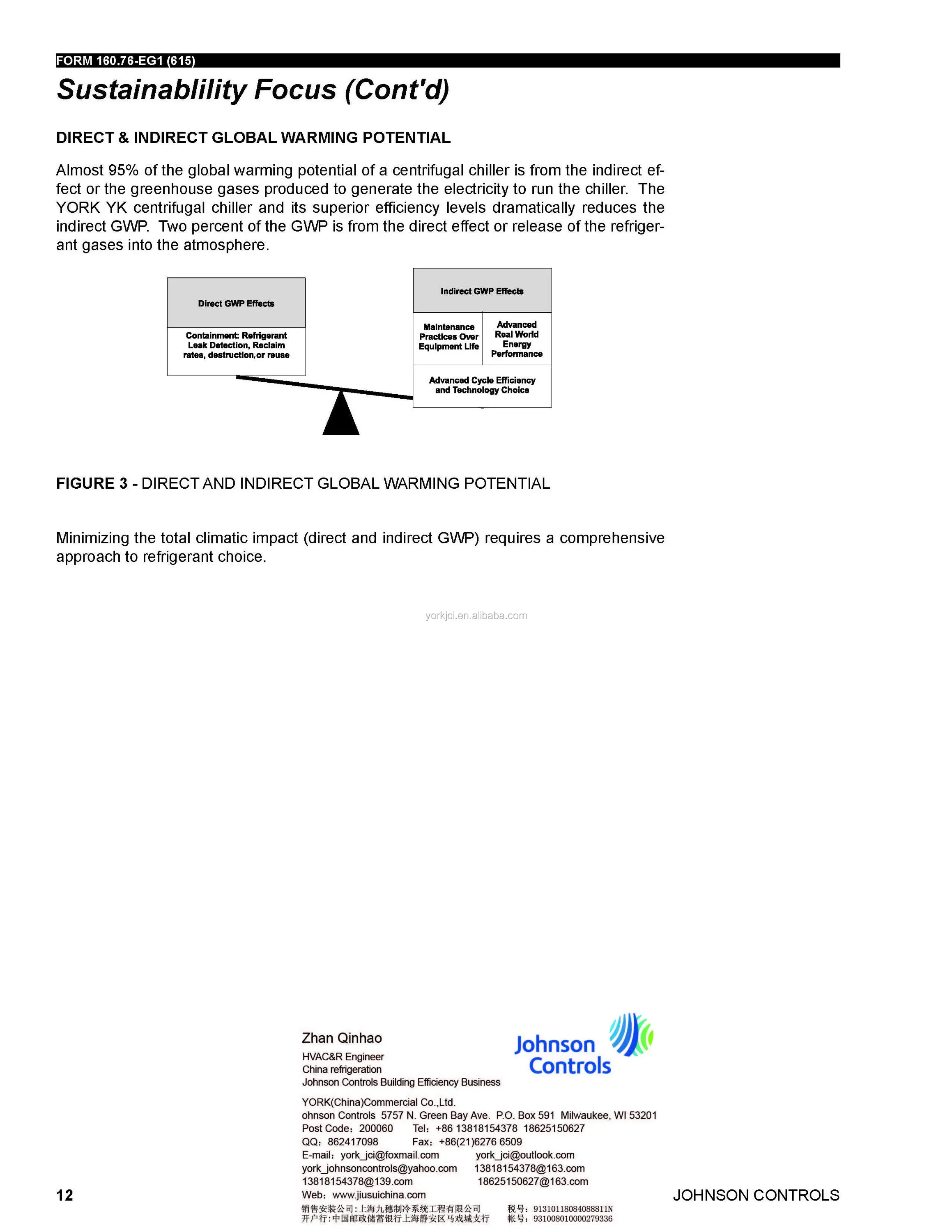

Quick Details

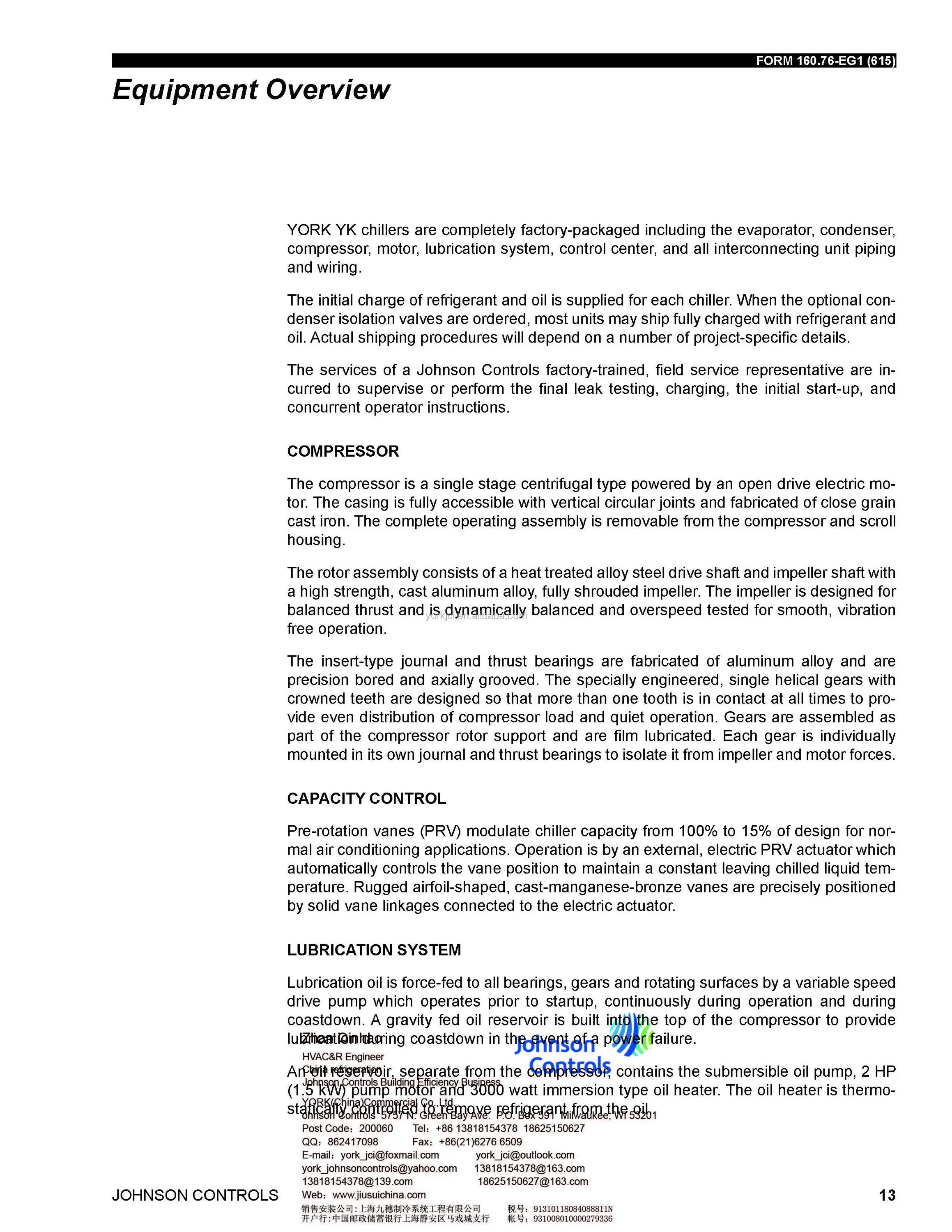

-

Brand Name: YORK

Model Number: YK-centrifugal compressor

Place of Origin: Jiangsu, China (Mainland)

Packaging & Delivery

- Packaging Details: 60days

- Delivery Detail: --

Specifications

The YORK YK Chillers, manufactured by Johnson Controls, offer a complete combination

of features for total owner satisfaction.

MATCHED COMPONENTS MAXIMIZE EFFICIENCY

Actual chiller efficiency cannot be determined by analyzing the theoretical efficiency of

any one chiller component. It requires a specific combination of heat exchanger, compressor,

and motor performance to achieve the lowest system kW/ton. YORK chiller technology

matches chiller system components to provide maximum chiller efficiency under

actual – not just theoretical – operating conditions.

REAL-WORLD ENERGY PERFORMANCE

Johnson Controls pioneered the concept of “Real-World Energy” to illustrate the energysaving

potential of focusing on chiller performance during off-design conditions. Off-design

is not only part load, but full load operation as well, with reduced entering condenser

water temperatures (ECWTs). This is where chillers operate 99% of the time, and where

operating costs add up.

YORK centrifugal chillers are the only chillers designed to operate on a continuous basis

with cold ECWT and full condenser flow at all load points, taking full advantage of Real-

World conditions. This type of operation benefits the cooling tower as well by reducing the

cycling of the fan motor and ensuring good coverage of the cooling fill.

YORK centrifugal chillers offer the most efficient Real-World operation of any chiller,

meaning lower operating costs and an excellent return on your chiller investment.

OPEN-DRIVE DESIGN

Hermetic motor burnout can cause catastrophic damage to a chiller. The entire chiller

must be cleaned, and the refrigerant replaced. YORK YK centrifugal chillers eliminate

this risk by utilizing air-cooled motors. Refrigerant never comes in contact with the motor,

preventing contamination of the rest of the chiller.

Insurance companies that offer policies on large air conditioning equipment often consider

air-cooled motors a significant advantage over hermetic refrigerant-cooled units.

HIGH EFFICIENCY HEAT EXCHANGERS

YORK YK chiller heat exchangers offer the latest technology in heat transfer surface design

to give you maximum efficiency and compact design. Waterside and refrigerant side

design enhancements minimize both energy consumption and tube fouling.

250 — 3000 TR

880 — 10,550 kW

Model YK—centrifugal compressor

Unique Features: OptiSpeed™ variable-speed drive, heat-recovery capability,

quick start feature, OptiSound™ control, OptiView™ control panel, equipped with

Smart Connected technology – a cloud-based analytics and monitoring system

Ideal Applications: comfort cooling, heat-recovery sites, data centers

2500 — 3500 TR

8800 — 12,300 kW

Model YK-EP—centrifugal compressors with economizer

Unique Features: higher efficiency at design and off-design conditions,

OptiSpeedTM variable-speed drive, single OptiView™ control panel, equipped with

Smart Connected technology – a cloud-based analytics and monitoring system

Ideal Applications: district cooling, process / industrial cooling, data centers,

turbine inlet-air cooling

SINGLE STAGE COMPRESSOR DESIGN AND EFFICIENCY PROVEN IN THE MOST

DEMANDING APPLICATIONS

Designed to be the most reliable chillers we’ve ever made, YORK YK centrifugal chillers

incorporate single-stage compressor design. With fewer moving parts and straightforward,

efficient engineering, YORK single-stage compressors have proven durability

records in hospitals, chemical plants, gas processing plants, the U.S. Navy, and in other

applications where minimal downtime is a crucial concern.

In thousands of installations worldwide, YORK single-stage compressors are working to

reduce energy costs. High strength aluminum-alloy compressor impellers feature backward

curved vanes for high efficiency. Airfoil shaped pre rotation vanes minimize flow disruption

for the most efficient part load performance. Precisely positioned and tightly fitted,

they allow the compressor to unload smoothly from 100% to minimum load for excellent

operation in air conditioning applications.

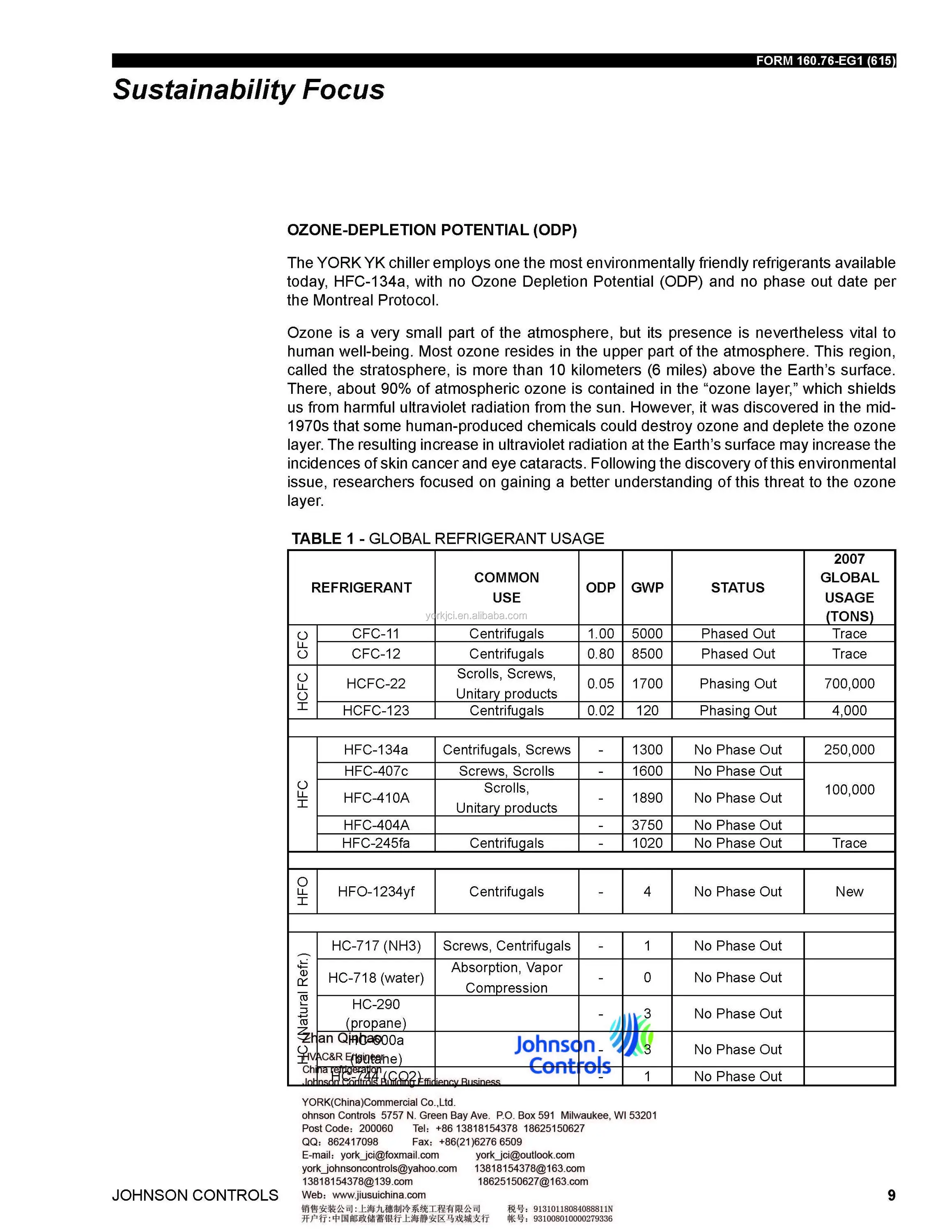

AHRI CERTIFICATION PROGRAM

YORK YK chillers have been tested and certified by Air-Conditioning, Heating and Refrigeration

Institute (AHRI) in accordance with the latest edition of AHRI Standard 550/590 (IP).

Under this Certification Program, chillers are regularly tested in strict compliance with

this Standard. This provides an independent, third-party verification of chiller performance.

Refer to the AHRI site at: http://www.ahrinet.org/water_chilling+packages+using+vap

or+compression+cycle+_water_cooled_.aspx for complete Program Scope, Inclusions,

and Exclusions as some options listed herein fall outside the scope of the AHRI certification

program. For verification of certification, go to the AHRI Directory at www.ahridirectory.

org.

PRECISION CONTROL OF COMPRESSOR OIL PRESSURE

Utilizing our expertise in variable speed drive technology and applications, Johnson Controls

has moved beyond the fixed head and bypass approach of oil pressure control. The

old approach only assures oil pressure at the outlet of the pump rather than at the compressor,

and allows no adjustment during chiller operation. The YORK YK chillers feature

a variable speed drive oil pump, monitoring and providing the right amount of oil flow to

the compressor on a continuous basis. This design also provides sophisticated electronic

monitoring and protection of the oil pump electrical supply, ensuring long life and reliable

operation of the oil pump motor. Variable speed drive technology reduces oil pump power

consumption, running only at the speed required, rather than at full head with a pressure

regulating bypass valve.

Ensure the fastest chiller restarts with Quick Start feature

Temperature-sensitive operations such as data center,

pharmaceutical, and manufacturing facilities require constant

cooling for equipment and processes. If power fails and cooling

is interrupted, critical operations may also fail — risking millions

of dollars in equipment failure and operational downtime.

Now there‘s a sure way to reduce the risk of cooling disruption —

the Quick Start feature from Johnson Controls. This feature for

YORK® centrifugal chillers with OptiSpeed™ variable-speed drive

can save you both time and money by:

• Reducing time for chiller restart after power failure

• Rapidly re-establishing chilled-water temperature

• Keeping process equipment cooled

• Reducing risks of expensive downtime

• Providing a faster initial start, too

Reduce restart time to seconds

After power is interrupted, it can take a standard centrifugal

chiller many minutes to restart. But with the Quick Start feature,

once power is restored, the chiller can restart in as little as

25 seconds!

However, we understand that your application does not just

require the chiller to restart, but needs the fastest delivery of

chilled water at the design temperature. In Figures 1, 2, and 3

on the next page, restart times are measured from the moment

the power fails, and the backup generator is assumed to have

established emergency power in 15 seconds.

Faster restarts due to smarter power management

The Quick Start feature is available in two configurations,

for use with or without an uninterruptible power supply (UPS):

Quick Start feature without UPS is fast:

• Once emergency power is established, the chiller can restart as soon as the OptiView™ control panel reboots (75 seconds) and the OptiSpeed drive precharges (25 seconds), assuming coastdown of the compressor has been completed. If emergency power is available after 15 seconds, the chiller

will restart in 115 seconds after power was lost.

Quick Start feature with UPS is faster:

• The UPS keeps the OptiView and OptiSpeed control circuits energized and the oil heater operative until the emergency generator is activated, which eliminates the need for control panel reboot. The chiller will restart in 60 seconds after power was lost.

Faster restart restores specified leaving chilled-water

temperature quicker

The Quick Start feature not only minimizes chiller restart time, it reduces the time required for the re-establishment of the design leaving chilled-water temperature (LCHWT). The Quick Start feature utilizes accelerated loading logic, with the inlet vanes fully open, to re-establish the specified leaving chilled-water temperature faster. While the actual time to re-establish the LCHWT will depend on plant design, compressor size, and operating conditions, a chiller equipped with the Quick Start option can cut the time by as much as 70%.

LCHWT:Standard LogicSetpointQuick Start with UPS10 minutes12 seconds3 minutes2 secondsTime from power failure (minutes)Temperature (degrees F)–20246810124042444648505254565860Standard ChillerQuick Start without UPSQuick Start with UPS249 seconds =about 4 minutes115 seconds =almost 2 minutes60 seconds15 sec.power failureLength of power failure (seconds)Time to restart from power loss (seconds)051020253035604080100120140160180200220240260280300320340Additional steps required if UPS not used*Coastdown time for a 500-ton chillerWithout UPSWith UPS60 seconds to restart with UPS115 seconds to restart1525PowerfailureVSD precharge6015607525Coastdown*Coastdown*VSD prechargePowerfailureOptiView Chiller control panel rebootTimeline from loss of power

Figure 1: Required steps when power interruption occurs

with and without UPS.

Figure 2: Restart times for 500-ton chiller.

Figure 3: Time to re-establish LCHWT for 500-ton chiller at low load.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai nine ear refrigeration systems engineering company tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York-Shanghai Nine Sui Refrigeration Systems Engineering Company Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Nine Sui Refrigeration Systems Engineering Company is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York-Shanghai nine-pan refrigeration system Engineering companies are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai nine Sui refrigeration systems engineering company food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai nine Sui refrigeration systems engineering company food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai nine Sui refrigeration systems engineering company frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.

Scale: Above 1000 People

Country/Region: China (Mainland)/Asia

Established: 2015

US 6181-87111 / Pack 1 Pack/Packs (Min.Order)

- Min.order FOB Price

- ≥1 Pack US 82100.00